Concrete Calculator

Enter dimensions, pick a shape, and choose density (use presets or custom). Volume is geometric; weight & bags depend on density.

Embed this calculator

Adjust the size if needed, then copy the code below into your page or blog. The calculator will load in an iframe and stay updated automatically.

✅ Works on most website builders (WordPress, Elementor, HTML, etc.) · Please keep the credit link to support future free tools.

🔹 Table of Contents

- Concrete Calculator

- How to Use the Concrete Calculator

- Concrete Volume Formulas by Shape

- Mix Density & Bag Sizes Explained

- Worked Examples by Shape

- Thickness, Strength & Slump Guide

- Ordering, Waste Allowance & Delivery Tips

- Irregular Shapes, Openings & Sloped Slabs

- Quick Bag Count Reference

- Bag Yield & Coverage per Bag

- Estimation Workflow

- Frequently Asked Questions

- References & Sources

🔹 How to Use the Concrete Calculator

This tool estimates concrete volume, weight, and bag counts for common shapes: slab/wall, hole/footing, circular slab/tube, curb & gutter, and stairs. You can mix units (feet, inches, yards, meters, centimeters) and choose a density preset or enter a custom density from your supplier.

- Select a shape (e.g., Slab / Wall).

- Enter dimensions and pick the unit beside each field.

- Set density:

- Default: Pre-mixed — 2130 kg/m³ (≈133 lb/ft³) — matches many retail mixes and the competitor example.

- Use Custom… to type your supplier’s density in kg/m³ or lb/ft³.

- Click Calculate to see:

- Volume in m³, yd³, and ft³,

- Weight in kg and lb,

- Bags needed — clearly grouped as 25 kg / 40 kg and 60 lb / 80 lb (rounded up, with exact values shown).

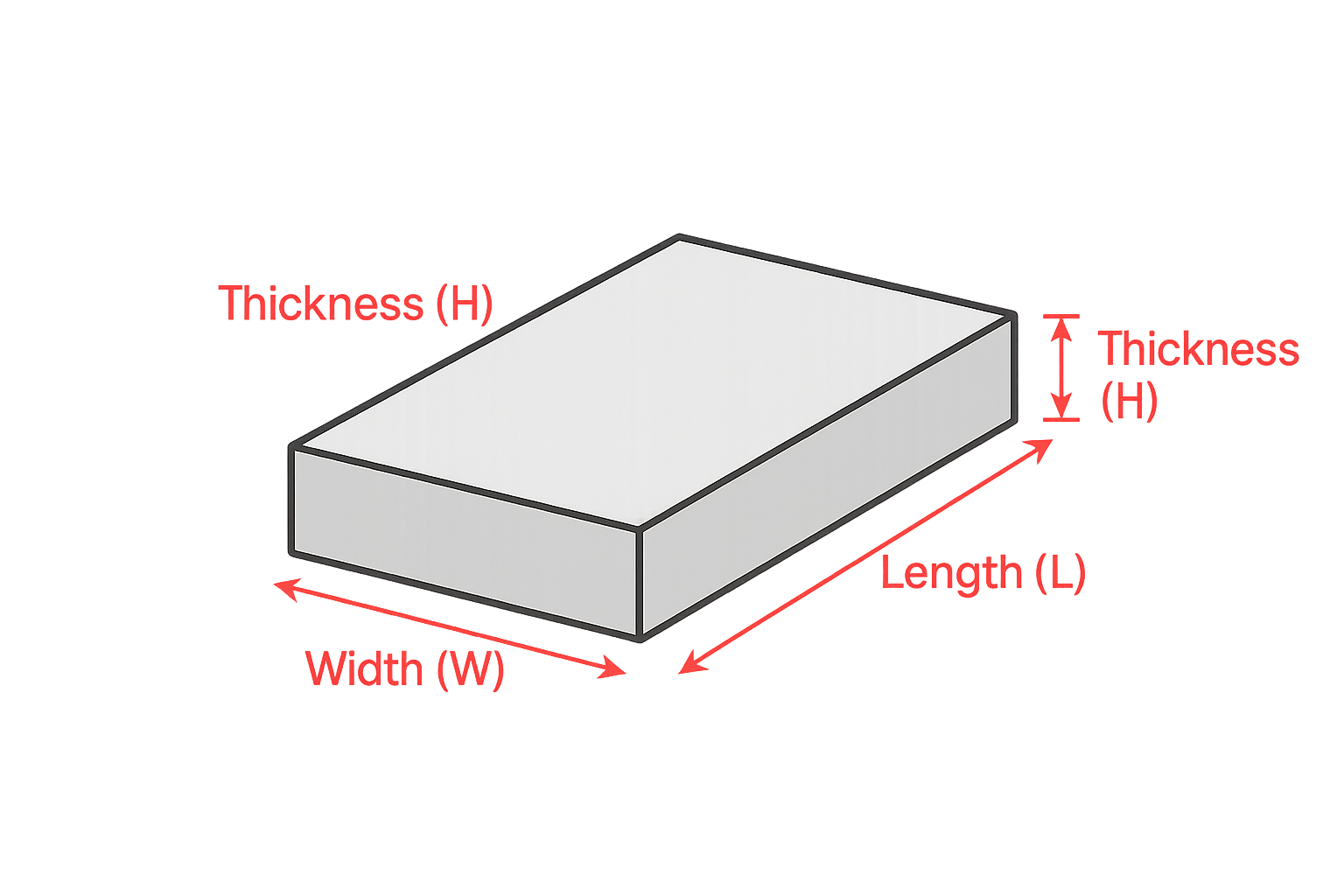

Slab volume:

V = L × W × HCylindrical hole:

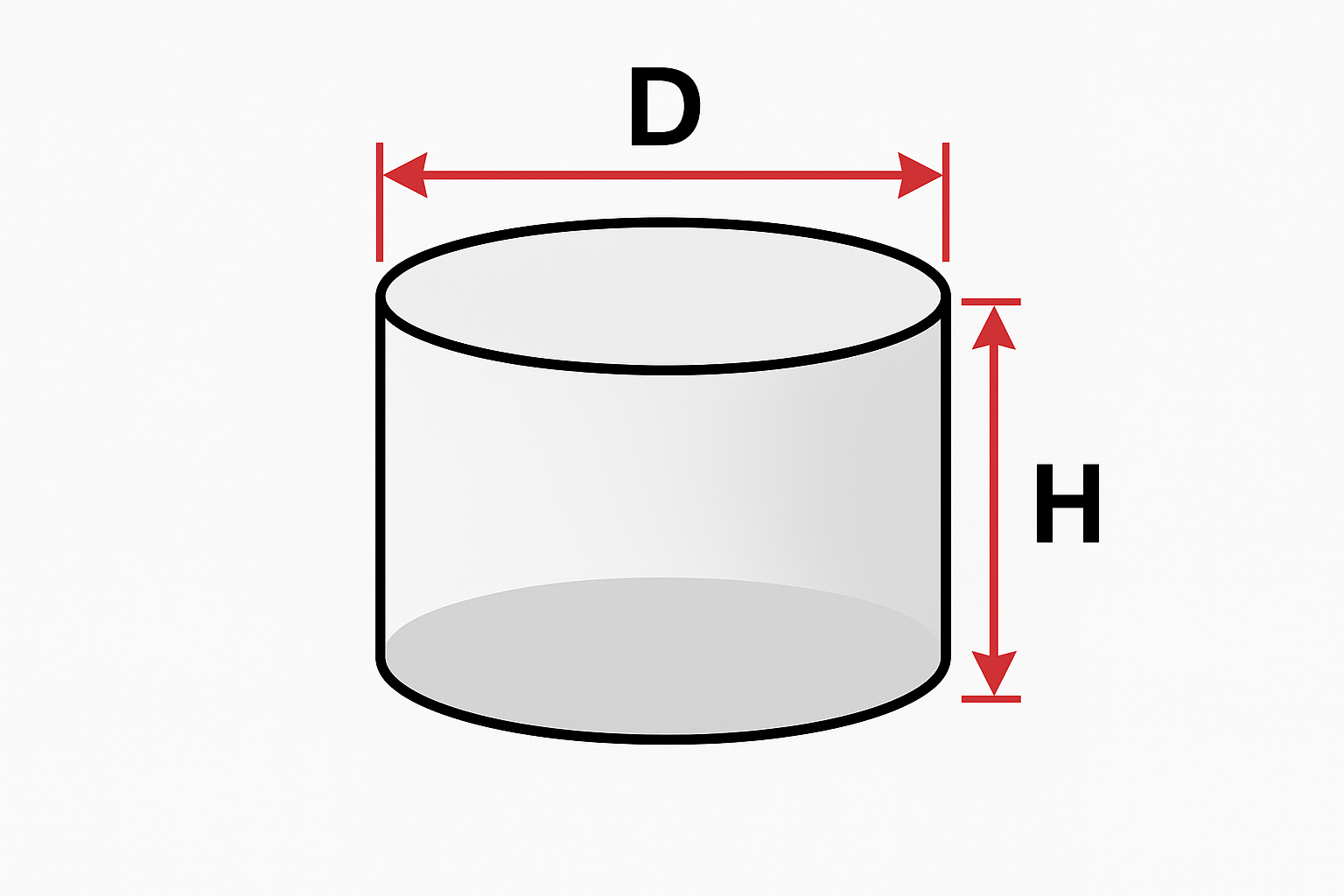

V = π × (D/2)² × HTube (annulus):

V = π × (d₁² − d₂²) / 4 × HStairs (approx.):

V ≈ 0.5 × run × rise × width × steps (+ platform) 🔹 Worked Example (matches competitor settings)

Slab with L = 15 m, W = 2.5 m, Thickness = 5 cm, Quantity = 1, density 2130 kg/m³:

- Thickness = 5 cm = 0.05 m → Volume = 15 × 2.5 × 0.05 = 1.875 m³ (≈ 2.452 yd³, 66.22 ft³).

- Weight = 1.875 × 2130 = 3,993.75 kg (≈ 8,807 lb).

- Bags (metric): 3,993.75/25 = 159.75 → 160 × 25 kg; 3,993.75/40 = 99.84 → 100 × 40 kg.

- Bags (US): 8,807/60 ≈ 146.78 → 147 × 60 lb; 8,807/80 ≈ 110.09 → 111 × 80 lb.

Planning tip: buy an extra 5–10% to cover waste, uneven subgrade, spillage, and small overbreaks. For metric/imperial conversions after you compute, try our Volume Conversion Calculator.

🔹 Concrete Volume Formulas by Shape

These are the exact geometric formulas the calculator uses before applying density for weight and bag counts. Units can be mixed on input; the tool converts everything to meters internally.

L = length, W = width, H = thickness/height/depth, D = diameter, d₁ = outer diameter, d₂ = inner diameter, run = tread depth per step, rise = riser height per step, steps = number of steps, width = stair width, plat = platform depth (optional). | Shape | Formula (Volume) | Notes |

|---|---|---|

| Slab / Wall (Rectangular) | V = L × W × H | Use thickness for H. Typical slab thicknesses: 75–150 mm (3–6 in). |

| Hole / Footing (Cylinder) | V = π × (D/2)² × H | Diameter is measured edge to edge. Depth is vertical height. |

| Circular Slab / Tube (Annulus) | V = π × (d₁² − d₂²)/4 × H | Set d₂ = 0 for a solid circular pier/slab. Use inner diameter for voids/liners. |

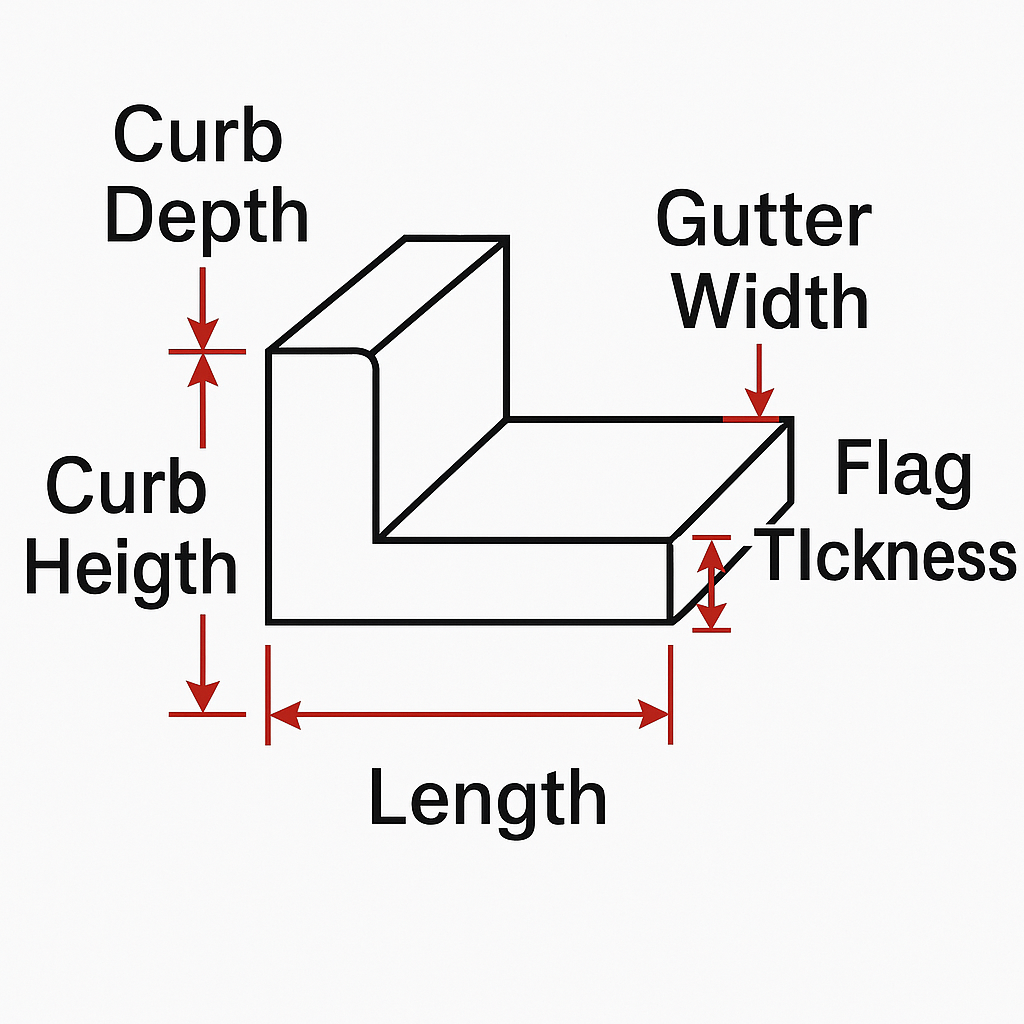

| Curb & Gutter (Approx.) | V ≈ (curbDepth × curbHeight + gutterWidth × flagThickness) × length | An engineering-friendly approximation treating curb and gutter as two rectangular prisms. |

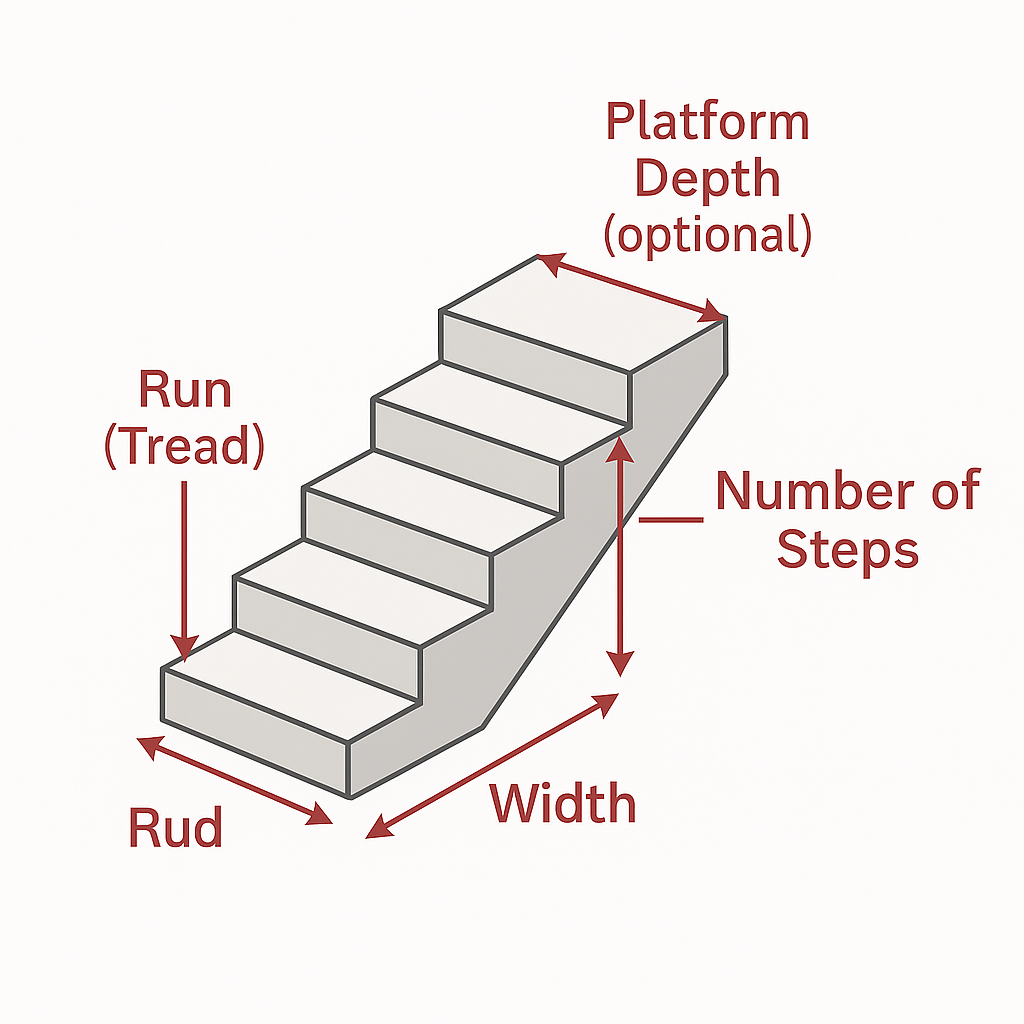

| Stairs (Approx.) | Vstairs ≈ 0.5 × run × rise × width × stepsVplatform ≈ plat × rise × widthV ≈ Vstairs + Vplatform | The triangular prism method closely matches poured stairs. Include platform if present. |

🔹 Accuracy & Tolerances

- Geometry drives volume. Density only affects weight and bag counts.

- Wastage allowance: add 5–10% to cover spillage, over-excavation, and uneven subgrade.

- Aggregate & slump: water content and aggregate grading change density slightly—use supplier specs if available (enter via Custom density).

- Reinforcement (rebar/mesh) displaces a small volume, usually negligible for most estimates.

Tip: If you only know area and thickness (e.g., a patio), compute volume with V = Area × Thickness. If you need quick conversions after calculating, you can use the Length, Area, or Volume converters on our site.

🔹 Mix Density & Bag Sizes Explained

Volume comes from geometry only. Weight and bag counts depend on the density you choose. We provide industry-typical presets and a custom option to match your supplier’s datasheet.

| Preset | kg/m³ | lb/ft³ (approx.) | When to use |

|---|---|---|---|

| Pre-mixed (default) | 2130 | ≈133 | Retail bag mixes and many online examples—matches our competitor’s reference values. |

| Normal weight | 2400 | ≈150 | Standard ready-mix with typical aggregates; yields heavier results than the default. |

| Standard | 2240 | ≈140 | Middle-ground reference for general estimates. |

| Lightweight | 2000 | ≈125 | Lightweight mixes—reduce weight & bag counts for the same volume. |

Bag counts in the calculator are computed by dividing the total mix weight by the bag mass. This keeps things consistent across metric and US sizes:

| Bag type | Bag mass | How the calculator uses it |

|---|---|---|

| Metric | 25 kg | Total kg ÷ 25 → rounds up to a whole bag (also shows exact decimal). |

| Metric | 40 kg | Total kg ÷ 40 → rounds up to a whole bag (with exact value). |

| US | 60 lb | Total lb ÷ 60 → rounds up to a whole bag (with exact value). |

| US | 80 lb | Total lb ÷ 80 → rounds up to a whole bag (with exact value). |

Important: Bag yields in ft³/yd³ vary by brand and moisture. Our approach uses weight-based bag counts so your density choice (or supplier’s spec via Custom) directly controls the estimate. If you only know area and thickness, compute volume first, then weight and bags follow automatically.

🔹 Worked Examples by Shape

All examples assume the default density 2130 kg/m³ (≈133 lb/ft³). Results include volume, weight, and bags needed (rounded up, with exact values shown in the calculator results).

Inputs:

L = 5 m, W = 3 m, Thickness H = 0.10 m, Qty = 1Volume:

V = L × W × H = 1.50 m³ (≈ 1.962 yd³, 52.97 ft³)Weight:

1.50 × 2130 = 3,195 kg (≈ 7,043.77 lb)Bags: Metric → 128 × 25 kg (exact 127.80), 80 × 40 kg (79.88); US → 118 × 60 lb (117.40), 89 × 80 lb (88.05).

Inputs:

Diameter D = 0.40 m, Depth H = 0.60 m, Qty = 4Volume:

V = π × (D/2)² × H × 4 = 0.3016 m³ (≈ 0.3945 yd³, 10.65 ft³)Weight:

0.3016 × 2130 = 642.39 kg (≈ 1,416.23 lb)Bags: Metric → 26 × 25 kg (25.70), 17 × 40 kg (16.06); US → 24 × 60 lb (23.60), 18 × 80 lb (17.70).

Inputs:

d₁ = 0.60 m (outer), d₂ = 0.40 m (inner), H = 1.20 m, Qty = 1Volume:

V = π × (d₁² − d₂²)/4 × H = 0.1885 m³ (≈ 0.2465 yd³, 6.66 ft³)Weight:

0.1885 × 2130 = 401.50 kg (≈ 885.15 lb)Bags: Metric → 17 × 25 kg (16.06), 11 × 40 kg (10.04); US → 15 × 60 lb (14.75), 12 × 80 lb (11.06).

Inputs:

curbDepth = 0.20 m, curbHeight = 0.15 m, gutterWidth = 0.40 m, flagThickness = 0.10 m, length = 6 mVolume:

V ≈ (0.20×0.15 + 0.40×0.10) × 6 = 0.4200 m³ (≈ 0.5493 yd³, 14.83 ft³)Weight:

0.4200 × 2130 = 894.60 kg (≈ 1,972.26 lb)Bags: Metric → 36 × 25 kg (35.78), 23 × 40 kg (22.37); US → 33 × 60 lb (32.87), 25 × 80 lb (24.65).

Inputs:

run = 0.30 m, rise = 0.18 m, width = 1.20 m, steps = 6, platformDepth = 0.50 mTriangular per step:

0.5 × run × rise × width = 0.0324 m³ → stairs total = 0.1944 m³Platform (assumes one rise high):

plat × rise × width = 0.1080 m³Volume:

V ≈ 0.3024 m³ (≈ 0.3955 yd³, 10.68 ft³)Weight:

0.3024 × 2130 = 644.11 kg (≈ 1,420.02 lb)Bags: Metric → 26 × 25 kg (25.76), 17 × 40 kg (16.10); US → 24 × 60 lb (23.67), 18 × 80 lb (17.75).

| Example | Volume (m³ / yd³ / ft³) | Weight (kg / lb) | Bags (25 kg / 40 kg / 60 lb / 80 lb) |

|---|---|---|---|

| Slab | 1.50 / 1.962 / 52.97 | 3,195 / 7,043.77 | 128 / 80 / 118 / 89 |

| Footings ×4 | 0.3016 / 0.3945 / 10.65 | 642.39 / 1,416.23 | 26 / 17 / 24 / 18 |

| Tube (annulus) | 0.1885 / 0.2465 / 6.66 | 401.50 / 885.15 | 17 / 11 / 15 / 12 |

| Curb & Gutter | 0.4200 / 0.5493 / 14.83 | 894.60 / 1,972.26 | 36 / 23 / 33 / 25 |

| Stairs | 0.3024 / 0.3955 / 10.68 | 644.11 / 1,420.02 | 26 / 17 / 24 / 18 |

Unit tips: If your drawings use imperial, our Length Conversion Calculator helps convert inches/feet/yards to metric before estimating.

🔹 Thickness, Strength & Slump Guide

Use these field-proven ranges to sanity-check your estimate before ordering. Always confirm with your local code, engineer, or supplier.

| Application | Typical Thickness | Compressive Strength | Notes |

|---|---|---|---|

| Patios / Walkways | 75–100 mm (3–4 in) | 20–25 MPa (≈3000–3500 psi) | Control joints at 1.5–2.5 m (5–8 ft) spacing; compact base and add 5–10% waste. |

| Driveways (cars/SUV) | 100–125 mm (4–5 in) | 25–32 MPa (≈3500–4500 psi) | Air-entrained in freeze–thaw climates; proper sub-base is critical. |

| Garage / Light Commercial | 125–150 mm (5–6 in) | 30–35 MPa (≈4000–5000 psi) | Consider wire mesh or rebar grid; verify load paths and joint layout. |

| Footings (typical) | Width & depth per design | 25–32 MPa (≈3500–4500 psi) | Depth below frost line; use our cylinder footing option for volume. |

| Stairs (poured) | Rise/run per code | 25–32 MPa (≈3500–4500 psi) | Use our stair method (triangular prism + platform) for volume. |

| Use | Typical Slump | Comment |

|---|---|---|

| General slabs | 75–100 mm (3–4 in) | Workable without excessive bleed; finishable for flatwork. |

| Footings / walls | 50–100 mm (2–4 in) | Lower slump reduces segregation in forms. |

| Pumped / congested rebar | 100–150 mm (4–6 in) | Plasticizers often used instead of water to maintain strength. |

- Reinforcement: mesh or rebar minimizes cracking; placement and cover matter.

- Joints: saw-cut control joints early (often within 6–12 hours) to guide shrinkage cracks.

- Curing: keep the slab moist and protected for at least 7 days for strength gain and durability.

Need quick area or weight conversions? Try our Area Conversion Calculator and Weight Conversion Calculator after you compute volume.

🔹 Ordering, Waste Allowance & Delivery Tips

After you calculate volume, decide whether to use bagged mix or ready-mix delivery. Always include a waste allowance (typically 5–10%) for spillage, uneven subgrade, and small plan changes.

| Project size (approx.) | Recommended supply | Why |

|---|---|---|

| < 0.5 m³ (≈ < 0.65 yd³) | Bagged mix | Lower total cost, easy scheduling; labor-intensive but manageable. |

| 0.5–2.0 m³ (≈ 0.65–2.6 yd³) | Depends on access & crew | Bagged if access is difficult or timing flexible; ready-mix if crew is available and placement is continuous. |

| > 2.0 m³ (≈ > 2.6 yd³) | Ready-mix delivery | Faster placement, consistent quality, often cheaper than many bags + labor. |

🔹 Waste Allowance

- Standard: order +5–10% beyond calculated volume.

- Complex forms / hard access: consider +10–15%.

- Pumped concrete: allow a bit extra for line priming and residual.

🔹 Delivery Checklist

- Access & reach: can a truck get close? If not, plan for a pump or buggies.

- Slump/Workability: confirm slump target with supplier; use admixtures instead of extra water to protect strength.

- Crew & tools ready: forms, reinforcement, screed, floats, and curing supplies on-site before truck arrives.

- Placement rate: match delivery time to crew speed to avoid cold joints.

- Weather plan: shade/windbreaks in heat; blankets or accelerators in cold; avoid heavy rain windows.

Quick tip: If you’re on the fence between bagged and ready-mix, compare your calculator’s bag counts to local ready-mix minimum load fees. For unit conversions after calculating, see our Volume Conversion Calculator.

🔹 Irregular Shapes, Openings & Sloped Slabs

Most real projects aren’t perfect rectangles. Use these quick rules to handle irregular edges, door/window openings, pier recesses, and falls (slopes) while keeping your estimate accurate.

Split your layout into rectangles, triangles, or circles. Calculate each piece, then sum volumes.

- Triangle slab corner: area =

½ × base × height→ volume =area × thickness. - Arc/segment: approximate with a sector or use a circular slab formula for the curved portion.

Any opening (e.g., a floor drain recess, access hatch, or sleeve) should be removed from the total:

- Rectangular opening:

V = L × W × H(same thickness as slab). - Round opening:

V = π × (D/2)² × H. - Annular void (liner/tube):

V = π × (d₁² − d₂²)/4 × H.

When a slab is cast to a fall (e.g., 80 mm at one edge, 120 mm at the other), use the mean thickness:

Havg = (Hmin + Hmax) / 2V = Area × Havg. | Scenario | Inputs | Calculation | Volume |

|---|---|---|---|

| Slab with opening + slope | Rectangular slab: L=6.0 m, W=4.0 mThickness varies: Hmin=0.08 m, Hmax=0.12 mOpening: round drain D=0.30 m, through slab | Area = 6×4 = 24 m²Havg = (0.08+0.12)/2 = 0.10 mSlab volume = 24 × 0.10 = 2.40 m³Opening volume = π × (0.30/2)² × 0.10 ≈ 0.0071 m³Net volume = 2.40 − 0.0071 | ≈ 2.393 m³ |

Tip: For pier caps, beams, or pads attached to a main pour, compute each element with the closest matching shape (rectangle or cylinder) and add them. If you later need conversions after the total is known, run the result through your on-page unit outputs (m³, yd³, ft³) or our converters.

🔹 Quick Bag Count Reference

Use this table for a fast order check at the default density 2130 kg/m³ (≈133 lb/ft³). For other densities (e.g., supplier-specific mixes), use the calculator’s Custom density option to recalc automatically.

| Volume | Weight | Bags (rounded up) |

|---|---|---|

| 0.10 m³ | 0.1308 yd³ | 3.53 ft³ | 213 kg | 470 lb | 25 kg: 9 | 40 kg: 6 | 60 lb: 8 | 80 lb: 6 |

| 0.25 m³ | 0.3270 yd³ | 8.83 ft³ | 532.5 kg | 1,174 lb | 25 kg: 22 | 40 kg: 14 | 60 lb: 20 | 80 lb: 15 |

| 0.50 m³ | 0.6540 yd³ | 17.66 ft³ | 1,065 kg | 2,348 lb | 25 kg: 43 | 40 kg: 27 | 60 lb: 40 | 80 lb: 30 |

| 0.75 m³ | 0.9810 yd³ | 26.49 ft³ | 1,597.5 kg | 3,522 lb | 25 kg: 64 | 40 kg: 40 | 60 lb: 59 | 80 lb: 45 |

| 1.00 m³ | 1.3080 yd³ | 35.31 ft³ | 2,130 kg | 4,696 lb | 25 kg: 86 | 40 kg: 54 | 60 lb: 79 | 80 lb: 59 |

| 1.50 m³ | 1.9620 yd³ | 52.97 ft³ | 3,195 kg | 7,044 lb | 25 kg: 128 | 40 kg: 80 | 60 lb: 118 | 80 lb: 89 |

| 2.00 m³ | 2.6159 yd³ | 70.63 ft³ | 4,260 kg | 9,392 lb | 25 kg: 171 | 40 kg: 107 | 60 lb: 157 | 80 lb: 118 |

How to use: find the row closest to your computed volume. If your job is complex (openings/slopes), calculate accurately with the tool first, then cross-check here. Always add 5–10% extra for waste.

🔹 Bag Yield & Coverage per Bag

These yields assume the calculator’s default density 2130 kg/m³ (≈133 lb/ft³). Actual yield varies with aggregate, slump and air content. Use this as a quick planning guide; the calculator’s bag counts remain the source of truth for your exact dimensions and chosen density.

| Bag size | Approx. wet volume (m³) | Approx. wet volume (ft³) | Approx. wet volume (yd³) |

|---|---|---|---|

| 25 kg | 0.01174 | 0.414 | 0.0153 |

| 40 kg | 0.01878 | 0.663 | 0.0246 |

| 60 lb | 0.01277 | 0.451 | 0.0167 |

| 80 lb | 0.01703 | 0.601 | 0.0223 |

Coverage per bag at common slab thicknesses (rounded, default density). Use this to sanity-check small pads or patch areas.

| Bag size | 2 in (50 mm) | 4 in (100 mm) | 6 in (150 mm) |

|---|---|---|---|

| 25 kg | ≈ 2.48 ft² | 0.235 m² | ≈ 1.24 ft² | 0.117 m² | ≈ 0.83 ft² | 0.078 m² |

| 40 kg | ≈ 3.98 ft² | 0.376 m² | ≈ 1.99 ft² | 0.188 m² | ≈ 1.33 ft² | 0.125 m² |

| 60 lb | ≈ 2.71 ft² | 0.256 m² | ≈ 1.35 ft² | 0.128 m² | ≈ 0.90 ft² | 0.085 m² |

| 80 lb | ≈ 3.61 ft² | 0.341 m² | ≈ 1.80 ft² | 0.170 m² | ≈ 1.20 ft² | 0.114 m² |

Reminder: These tables reflect the default density. If your supplier confirms a different density, switch the calculator to Custom density—the bag counts and implied yields update automatically.

🔹 Estimation Workflow: From Plan to Bag Count

Follow this simple workflow to go from drawings to an order you can place with confidence. It works for all shapes in the calculator: slab/wall, hole/footing, circular slabs & tubes, curb & gutter, and stairs.

- Measure your dimensions from plans or on-site (length, width/diameter, thickness/height, quantity). If the slab is sloped, use

Havg = (Hmin + Hmax)/2. - Choose the closest shape in the calculator. Break complex layouts into simple pieces and subtract openings/voids.

- Enter units beside each field (feet, inches, yards, meters, centimeters). The tool converts everything internally.

- Select density: keep the default 2130 kg/m³ (≈133 lb/ft³) or use Custom to match supplier specs (kg/m³ or lb/ft³).

- Calculate to get volume (m³/yd³/ft³), weight (kg/lb), and bags grouped by metric (25/40 kg) and US (60/80 lb).

- Add waste (usually 5–10%). For tight forms, hard access, or pumping, consider 10–15%.

- Check logistics: crew size, placement rate, ready-mix minimums vs many small bags, equipment (screed, float, cure materials).

Patio area:

5.0 m × 3.5 m, thickness 100 mm; one door recess 0.9 m × 0.2 m through slab.Volume =

(5×3.5×0.10) − (0.9×0.2×0.10) = 1.75 − 0.018 = 1.732 m³.In the calculator: choose Slab, enter values, set density, then read off weight & bags (rounded-up counts for 25/40 kg and 60/80 lb).

| Common mistake | Fix |

|---|---|

| Mixing units (e.g., entering inches but thinking feet) | Use the unit dropdown beside each field; the tool handles conversions for you. |

| Forgetting openings or voids | Subtract each opening volume using rectangle/circle formulas, or use the Tube (annulus) for liners. |

| Ignoring slope (falls to a drain) | Use average thickness: (min + max)/2 to get an accurate volume. |

| Under-ordering bags | Always add 5–10% waste; the calculator shows exact vs rounded-up bag counts. |

Next step: When your volume is finalized, confirm delivery windows and slump with your supplier, then plan curing (keep the slab moist/protected for at least 7 days).

🔹 Frequently Asked Questions

Use the default 2130 kg/m³ (≈133 lb/ft³) to match many retail mixes and competitor examples. If your supplier provides a specific density (or you’re using lightweight or high-density mixes), choose Custom… and enter it in kg/m³ or lb/ft³. Volume doesn’t change—only weight and bag counts do.

About 45 bags of 80 lb per cubic yard (typical yield ≈ 0.6 ft³ per 80 lb bag). For 60 lb, it’s ~60 bags. Our calculator lists rounded-up bag counts and shows the exact decimals too.

Common guidance: 3–4 in (75–100 mm) for patios/walkways, 4–5 in (100–125 mm) for driveways, and 5–6 in (125–150 mm) for garages/light commercial. Always confirm with local code or an engineer.

Use the average thickness: Havg = (Hmin + Hmax)/2. Multiply area by Havg to get volume. Then add a 5–10% waste allowance before ordering.

Yes. We recommend +5–10% for most pours, and up to +10–15% for complex forms, pumping, or hard access. The calculator shows precise volume; add your waste on top when ordering.

Calculate the main slab volume, then subtract the opening volumes (rectangle or circle formula). For liners/tubes, use the Circular Slab / Tube (annulus) shape to compute the void and subtract it.

Volumes should match if dimensions are the same. Differences usually come from density assumptions and rounding rules for bag counts. Set density to the same value (e.g., 2130 kg/m³) to align results.

We calculate exact decimals and then show the rounded-up whole bags. Real-world yields vary with slump, aggregate, moisture, and placement waste—always add a small overage to your order.

Reinforcement helps control cracking and improve load distribution. Requirements depend on local code, loads, and soil. For driveways/garages, reinforcement or fiber is common—consult your engineer/supplier.

Yes. Each input has its own unit dropdown. The tool converts everything internally and outputs volume in m³, yd³, and ft³ plus weight and clear bag counts for both metric and US sizes.

🔹 References & Sources

These references informed our formulas, density presets, unit conversions, and practical guidance on thickness, slump, and bag yields.

| Source | What we used it for | Link / ISBN |

|---|---|---|

| Wolfram MathWorld — Cylinder, Annulus, Prism | Geometric volume formulas for cylinder, annulus (tube), and prisms (slab/stairs approximation). | Cylinder • Annulus • Prism |

| Engineering ToolBox — Concrete & material densities | Typical density ranges for normal-weight and lightweight concrete (e.g., ≈2000–2400 kg/m³). | engineeringtoolbox.com/density-materials |

| NRMCA — Concrete in Practice (CIP #8 Slump, others) | Guidance on slump/workability ranges and admixtures (used in our slump table and notes). | nrmca.org/concrete-in-practice |

| ACI 302.1R — Guide for Concrete Floor and Slab Construction | Industry reference for slab construction practices (thickness ranges, joints). | ACI 302.1R overview |

| ACI 360R — Design of Slabs-on-Ground | Background reference for slab thickness/usage categories mentioned in guidance tables. | ACI 360R overview |

| Portland Cement Association — Design and Control of Concrete Mixtures | General properties of concrete: density, materials, workability, curing practice. | ISBN 978-0-89312-217-1 • cement.org/design-control |

| QUIKRETE® — Concrete Mix (#1101) Product Data | Typical bag yield references (e.g., ~0.6 ft³ for 80 lb; ~0.45 ft³ for 60 lb) used to validate bag sections. | quikrete.com/productlines/concretemix.asp |

| SAKRETE® — High-Strength Concrete Mix | Cross-check of US bag yields and coverage guidance for 60/80 lb bags. | sakrete.com/product/high-strength-concrete-mix |

| NIST — Special Publication 811 (SI Guide) | Unit usage conventions; basis for consistent metric/US unit representation. | nist.gov/pml/special-publication-811 |

| US conversion constants | m³→yd³ (1 m³ ≈ 1.30795 yd³), m³→ft³ (1 m³ ≈ 35.3147 ft³), lb/ft³→kg/m³ (×16.0185) used in calculations. | engineeringtoolbox.com (conversion) |