Rebar Calculator

Estimate rebar quantity, length and weight for a rectangular concrete slab.

Total bars along length (across width): 0

Total bars along width (across length): 0

Total rebar length: 0

Estimated rebar weight: 0

Approximate stock bars needed: 0

| Direction | Bars | Length per bar | Total length |

|---|

Have an idea or spotted an issue?

Send a quick suggestion about this calculator. We read every message and use it to improve future updates.

Embed this calculator

Adjust the size if needed, then copy the code below into your page or blog. The calculator will load in an iframe and stay updated automatically.

✅ Works on most website builders (WordPress, Elementor, HTML, etc.) · Please keep the credit link to support future free tools.

🔹 Table of Contents

- Rebar Calculator

- What the Rebar Calculator Does

- How the Rebar Calculator Works

- Rebar Sizes, Spacing and Cover

- Worked Example: Small Patio Slab

- Practical Use, Planning and Limitations

- Real-Life Scenarios and Planning Checklist

- Measurement Tips and Common Input Mistakes

- Rebar Cost Estimation and Material List

- Step-by-Step Guide: Using the Rebar Calculator

- Online Rebar Calculator vs Manual Methods

- Rebar Calculator Key Takeaways

- Rebar Calculator FAQ

- References & Sources

🔹 What the Rebar Calculator Does

The Rebar Calculator on this page helps you estimate how much reinforcing steel you need for a rectangular concrete slab. It uses your slab length and width, chosen bar spacing, concrete cover, bar size, and stock bar length to work out the number of bars, total bar length and estimated rebar weight.

This is especially useful when you are planning driveways, garage floors, garden patios, shed bases, or house slabs and want a quick way to size your steel order before speaking to a supplier or structural engineer.

Behind the scenes, the calculator:

- Converts your spacing into a regular grid over the usable slab area (after cover).

- Calculates how many bars fit in each direction using “equal or under” spacing.

- Multiplies the bar count by bar length to get total rebar length.

- Uses standard weight-per-meter (metric) or weight-per-foot (US) tables to estimate total weight.

- Divides the total length by your chosen stock bar length to estimate how many stock bars to buy.

The grid visualisation above the results gives a simplified top view of the slab, showing the cover zone and an approximate rebar layout. It is designed to help you quickly check if your spacing and cover values look reasonable before you pour concrete.

🔹 How the Rebar Calculator Works

To keep your estimates practical and easy to understand, this Rebar Calculator uses a straightforward set of engineering-friendly formulas. It is designed for one layer of rebar in a flat slab with straight bars and constant spacing.

1. Effective slab dimensions (after cover)

Concrete cover protects the steel from corrosion and fire. The calculator subtracts the cover on all sides to find the area where reinforcing can actually be placed:

Linner = Lslab − 2 × coverWinner = Wslab − 2 × cover

In the metric mode, cover and spacing are entered in millimetres and converted to meters. In US / Imperial mode, they are entered in inches and converted to feet.

2. Number of bars in each direction

You enter a target spacing for bars in each direction. The calculator ensures the actual spacing is equal to or less than your chosen value by rounding the bar count up:

-

Bars across slab width (running along length):

Barswidth = ceil( Winner / spacingwidth ) + 1 -

Bars across slab length (running along width):

Barslength = ceil( Linner / spacinglength ) + 1

This is why the final spacing in the diagram may be slightly smaller than the value you typed – which is usually preferable for structural safety.

3. Length of each bar and total rebar length

Each set of bars is drawn across the full inner dimension in the perpendicular direction:

Bar length (along slab length) = LinnerBar length (along slab width) = Winner

Total rebar length is then:

Total length = Barswidth × Linner + Barslength × Winner

4. Total steel weight and stock bar count

Using standard rebar tables, each bar size has a fixed weight per unit length:

- Metric:

kg/mfor Ø6, Ø8, Ø10, Ø12, Ø16, Ø20 - US:

lb/ftfor #3, #4, #5, #6

The calculator multiplies total length by weight per unit length:

Total weight = Total length × (weight per meter or per foot)

Finally, your stock bar length (for example 6 m or 20 ft) is used to estimate how many full bars you need:

Stock bars = ceil( Total length / Stock length )

For planning concrete volume and thickness on the same project, you can pair this tool with the Concrete Calculator so you estimate both concrete and rebar on one page.

🔹 Rebar Sizes, Spacing and Cover

Choosing the right bar size, spacing and cover is just as important as knowing the total rebar weight. While final design should always follow local building codes or an engineer’s specification, the table and notes below explain how the inputs in this rebar calculator relate to what you see on real projects.

Rebar size overview

The calculator supports common metric diameters (Ø 6–20 mm) and US bar numbers (#3–#6). Each size has a standard weight per meter or per foot, which is used to estimate total steel weight.

| System | Typical sizes in this calculator | Common slab uses |

|---|---|---|

| Metric | Ø 8 mm, Ø 10 mm, Ø 12 mm | Patios, shed slabs, light driveways, internal floors |

| Metric (heavier) | Ø 16 mm, Ø 20 mm | Heavier loads, thicker structural slabs (engineer designed) |

| US / Imperial | #3, #4 | Sidewalks, garden paths, light-use slabs |

| US / Imperial (heavier) | #5, #6 | Garage slabs, small commercial slabs (per engineer) |

Typical slab rebar spacing

For many small residential slabs, rebar is often placed in a grid pattern between 150 mm and 300 mm (6–12 inches). Tighter spacing generally increases stiffness and crack control but also increases steel cost.

- Light duty slabs (paths, small patios): spacing may be closer to 200–300 mm (8–12").

- Medium duty slabs (driveways, garages): spacing is often 150–200 mm (6–8").

- Heavy or engineered slabs: spacing and bar size should follow a structural design.

In the calculator, you can experiment with different spacing values and instantly see how bar count and total rebar weight change. The diagram above also updates to show a denser or looser grid so you can visualise the impact of your choices.

Concrete cover basics

Concrete cover is the thickness of concrete between the outside surface and the nearest rebar. Adequate cover helps:

- Protect steel from corrosion and moisture.

- Improve fire resistance.

- Ensure the rebar “works” with the surrounding concrete.

The cover value you enter is applied on all four edges of the slab in the calculator. A larger cover reduces the inner area available for bars, which the grid visualisation shows as a red inner rectangle. If you increase cover too much for a very small slab, the tool will warn you that the remaining area is not large enough for a rebar grid.

🔹 Worked Example: Small Patio Slab

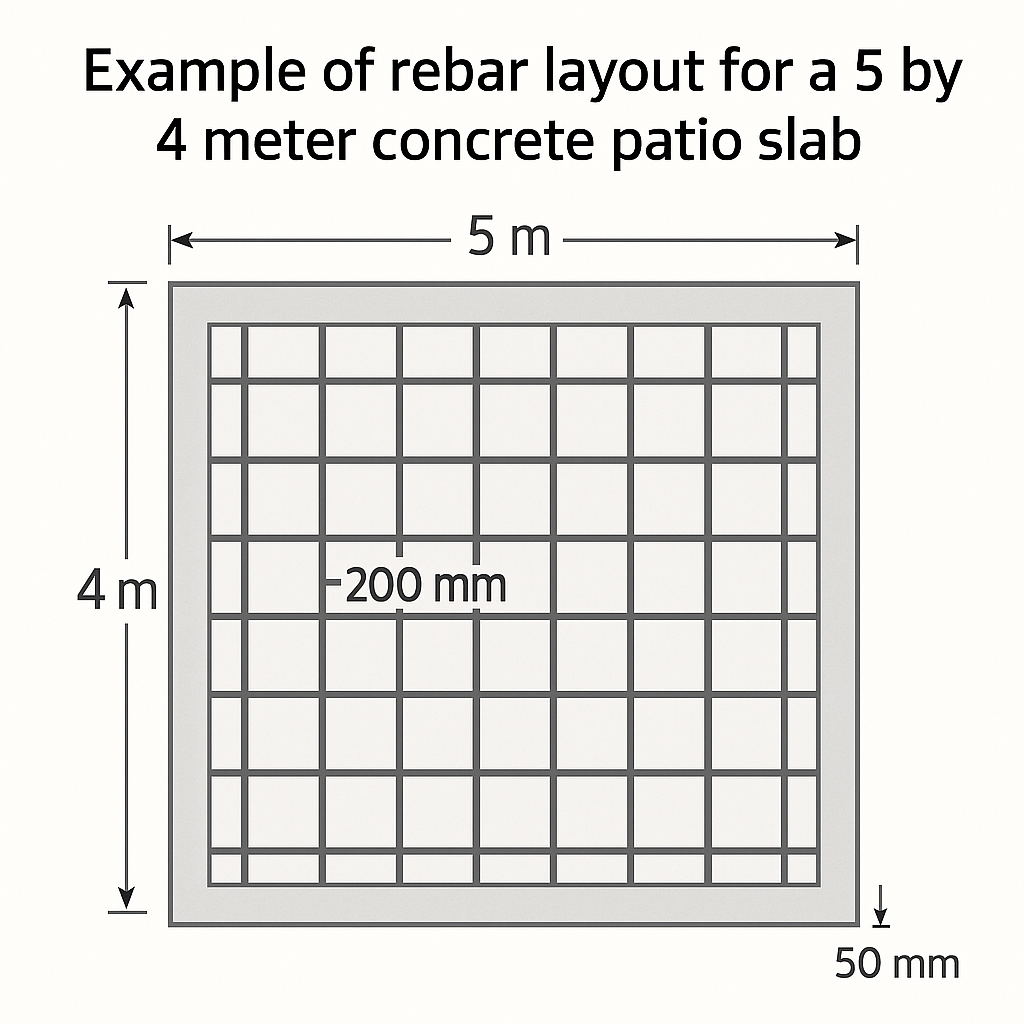

This example shows how the Rebar Calculator works for a typical backyard patio slab. You can plug the same numbers into the calculator at the top of the page to see identical results and the matching grid visualisation.

Scenario

Suppose you are pouring a reinforced concrete patio with the following details:

- Slab size: 5.0 m (length) × 4.0 m (width)

- Concrete cover: 50 mm on all sides

- Rebar spacing in both directions: 200 mm

- Rebar size: Ø 10 mm (weight ≈ 0.617 kg/m)

- Stock bar length: 6 m

1. Effective dimensions (after cover)

First, the calculator removes the cover on each edge:

- Cover = 50 mm = 0.05 m

- Inner length ≈ 5.0 − 2 × 0.05 = 4.9 m

- Inner width ≈ 4.0 − 2 × 0.05 = 3.9 m

2. Number of bars

Spacing is converted to meters: 200 mm = 0.20 m. The calculator uses “equal or under” spacing by rounding the bar count up:

| Direction | Inner span | Target spacing | Bars (result) | Approx. actual spacing |

|---|---|---|---|---|

| Across width (bars run along 4.9 m length) | 3.9 m | 0.20 m | 21 bars | 3.9 ÷ (21 − 1) ≈ 0.195 m (195 mm) |

| Across length (bars run along 3.9 m width) | 4.9 m | 0.20 m | 26 bars | 4.9 ÷ (26 − 1) ≈ 0.196 m (196 mm) |

The actual spacing is slightly tighter than 200 mm, which matches normal practice: it keeps spacing at or below the target distance.

3. Total rebar length and weight

Bar length in each direction equals the inner dimension:

- Bars across width: bar length ≈ 4.9 m

- Bars across length: bar length ≈ 3.9 m

Total length:

- Along length: 21 × 4.9 ≈ 102.9 m

- Along width: 26 × 3.9 ≈ 101.4 m

- Total ≈ 102.9 + 101.4 = 204.3 m

With Ø 10 mm rebar at about 0.617 kg/m:

- Total weight ≈ 204.3 × 0.617 ≈ 126 kg of steel

4. Number of stock bars to order

Using 6 m stock bars:

- Stock bars = ceil(204.3 ÷ 6) ≈ ceil(34.05) = 35 bars

In practice, contractors often add a small allowance for wastage or offcuts, but this gives a solid starting point when requesting quotes from suppliers.

If you also want to double-check the slab area for paving or finishes, you can use the Square Footage Calculator to quickly convert between square meters and square feet before ordering materials.

🔹 Practical Use, Planning and Limitations

The Rebar Calculator is designed as a fast planning tool for builders, DIY users, and estimators who need quick answers on steel quantity for simple slabs. It is not a replacement for a structural design, but it can save time when preparing budgets and material lists.

Best ways to use this calculator

- Early budgeting: get a quick estimate of total kilograms or pounds of rebar before asking suppliers for prices.

- Comparing options: try different bar sizes and spacing to see how steel weight changes for the same slab.

- Site planning: use the grid visualisation to talk through layout with installers and to plan where mesh chairs and joints might go.

- Ordering stock lengths: adjust the stock bar length to match what your local supplier carries and see how many full bars you should order.

What this calculator assumes

To keep things simple and fast, the tool makes several assumptions:

- The slab is perfectly rectangular with straight edges.

- There is one layer of rebar placed at a single level.

- Bars are straight, with no hooks, bends or laps added.

- Spacing is uniform in both directions across the whole slab.

- There are no openings, recesses, thickened edges or step changes in thickness.

If your slab has irregular shapes, beams, thickened edges, or multiple layers of reinforcement, you will need a more detailed take-off and proper structural design.

Limitations and safety notes

- Always follow your local building codes and any engineer’s drawings. Use this calculator to support planning, not to override professional advice.

- The weight values are based on standard rebar tables. Actual bar weights from manufacturers may vary slightly.

- The stock bar estimate does not include waste from cutting, overlaps or hooks. On real jobs, contractors typically add a percentage for wastage.

- For slabs carrying heavy point loads, machinery, or vehicles, a qualified engineer should specify both bar size and layout.

Used correctly, this Rebar Calculator gives you a clear, visual and numeric starting point for ordering steel and planning your pour, while still leaving final structural checks to the relevant design professional.

🔹 Practical Use, Planning and Limitations

The Rebar Calculator is designed as a fast planning tool for builders, DIY users, and estimators who need quick answers on steel quantity for simple slabs. It is not a replacement for a structural design, but it can save time when preparing budgets and material lists.

Best ways to use this calculator

- Early budgeting: get a quick estimate of total kilograms or pounds of rebar before asking suppliers for prices.

- Comparing options: try different bar sizes and spacing to see how steel weight changes for the same slab.

- Site planning: use the grid visualisation to talk through layout with installers and to plan where mesh chairs and joints might go.

- Ordering stock lengths: adjust the stock bar length to match what your local supplier carries and see how many full bars you should order.

What this calculator assumes

To keep things simple and fast, the tool makes several assumptions:

- The slab is perfectly rectangular with straight edges.

- There is one layer of rebar placed at a single level.

- Bars are straight, with no hooks, bends or laps added.

- Spacing is uniform in both directions across the whole slab.

- There are no openings, recesses, thickened edges or step changes in thickness.

If your slab has irregular shapes, beams, thickened edges, or multiple layers of reinforcement, you will need a more detailed take-off and proper structural design.

Limitations and safety notes

- Always follow your local building codes and any engineer’s drawings. Use this calculator to support planning, not to override professional advice.

- The weight values are based on standard rebar tables. Actual bar weights from manufacturers may vary slightly.

- The stock bar estimate does not include waste from cutting, overlaps or hooks. On real jobs, contractors typically add a percentage for wastage.

- For slabs carrying heavy point loads, machinery, or vehicles, a qualified engineer should specify both bar size and layout.

Used correctly, this Rebar Calculator gives you a clear, visual and numeric starting point for ordering steel and planning your pour, while still leaving final structural checks to the relevant design professional.

🔹 Real-Life Scenarios and Planning Checklist

Once you understand how the Rebar Calculator works, the next step is using it on real projects. The examples below show typical situations where a quick rebar estimate helps you avoid surprises on site and when ordering materials.

1. Driveway or parking bay

A reinforced driveway or small parking area is one of the most common uses for a slab rebar grid. You can:

- Enter the full length and width of the driveway, including any thickened edge strip.

- Choose a tighter spacing (for example 150–200 mm or 6–8") for areas where cars will sit.

- Adjust bar size to match the engineer’s or supplier’s recommendation for vehicle loads.

2. Garden shed or workshop base

For a garden shed, home office or small workshop, the main goal is usually to limit cracking and provide a flat, stable base:

- Measure the internal footprint of the shed and add any extra overhang you plan.

- Use medium spacing (around 200 mm / 8") with moderate bar sizes like Ø 10 mm or #4.

- Check the stock length result so you can cut bars efficiently with minimal waste.

3. Patio or terrace around a house

Patios and terraces often wrap around corners and door openings. A rectangular rebar grid still works well for the main areas:

- Model the largest rectangle first to get a baseline steel quantity.

- Add shorter offcuts or extra bars on site where the slab steps in or out.

- Use the visualisation to confirm that your cover and spacing look realistic near edges and steps.

4. Quick pre-order checklist

Before you place a steel order, run through this short checklist alongside the calculator results:

- Confirm slab size and thickness are final (no last-minute design changes).

- Check bar size and spacing against drawings or local code guidance.

- Verify stock bar length options with your supplier (for example 6 m, 12 m, 20 ft, 40 ft).

- Add a realistic allowance for cutting, overlaps and wastage.

- Note down bar size, total weight and number of stock bars for your purchase order.

With a few measurements and this Rebar Calculator, you can walk into a builder’s merchant or speak to your steel supplier already knowing roughly how many bars and how much weight you need, which makes getting accurate quotes much easier.

🔹 Measurement Tips and Common Input Mistakes

Accurate input values are essential if you want realistic quantities from this Rebar Calculator. Small measurement errors can quickly add up, especially on larger slabs, so it is worth double-checking before you order materials.

Measure the slab the way it will be poured

- Measure overall slab length and width, including any planned overhang beyond walls or formwork.

- Use a steel tape or laser measure where possible; soft tape measures can sag on long distances.

- If the slab edges are not perfectly straight, measure the longest side and round up slightly rather than down.

Metric vs US / Imperial inputs

To reduce confusion, the calculator clearly labels what each field expects:

- In Metric mode, length and width are in meters, spacing and cover in millimetres, and stock length in meters.

- In US / Imperial mode, length and width are in feet, spacing and cover in inches, and stock length in feet.

- Avoid converting in your head if possible – stick to the units shown on screen and let the calculator handle the conversions internally.

Typical mistakes to avoid

- Mixing units: entering slab length in feet while the calculator is set to metric, or mixing up inches and millimetres in spacing.

- Forgetting cover: using spacing that only fits if bars start right at the edge of the slab, without concrete cover.

- Using spacing that is too large: very wide spacing can produce too few bars, which may not control cracking effectively, even if the calculator can compute a result.

- Ignoring shape changes: the tool assumes a perfect rectangle; if your slab has steps or cut-outs, you may need to split it into several rectangles and run the calculation more than once.

When in doubt, sketch your slab on paper with rough dimensions and note down the inputs you used in the calculator. This makes it much easier to double-check your work or discuss the layout with a builder, engineer or supplier before you finalise an order.

🔹 Turning Rebar Quantities into a Cost Estimate

The Rebar Calculator gives you three key numbers for ordering and pricing: total rebar length, total steel weight and approximate number of stock bars. With a price list from your supplier you can quickly turn these into a project cost estimate.

1. Decide how you want to price rebar

Most suppliers quote reinforcing steel using one of three methods:

- Price per kilogram or per pound (for example €/kg or $/lb).

- Price per meter or per foot of a specific bar size.

- Price per stock bar at fixed lengths (for example 6 m bars).

The calculator supports all three by showing the total weight, total length and the number of stock bars you need.

2. Quick cost estimate from calculator outputs

Once you have your supplier’s pricing, you can build a simple estimate:

| Pricing method | Use this calculator value | Example cost calculation |

|---|---|---|

| Price per kg / lb | Total weight | Cost = Total weight × Price per kg |

| Price per meter / foot | Total length | Cost = Total length × Price per meter |

| Price per stock bar | Approx. stock bars needed | Cost = Bars × Price per bar |

For more accurate budgeting, you can also add line items for chairs, spacers, tying wire and mesh sheets if you are combining rebar with mesh reinforcement.

3. Building a simple material list

Use the results from the Rebar Calculator as the backbone of your materials list:

- Bar size and grade (for example Ø 10 mm, B500 or #4, Grade 60).

- Number of stock bars and standard length (for example 35 × 6 m bars).

- Total estimated weight for checking truck or delivery capacity.

- Any additional bars you plan for thickened edges, steps or openings.

If the slab will be finished with paving or tiles, you can combine this list with the surface area from the rebar inputs and use the Tile Calculator to estimate how many tiles and boxes you need for the same project.

4. When to ask for a detailed quote

Use your rebar quantity estimate as a starting point, then send it to one or more suppliers for a detailed quote that includes delivery, cutting services and any special bends or cages. Having clear numbers from this calculator usually leads to faster, clearer pricing and fewer surprises when the materials arrive on site.

🔹 Step-by-Step Guide: Using the Rebar Calculator

This step-by-step guide walks you through a typical use of this online rebar calculator for concrete slabs. You can follow the list below while looking at the calculator at the top of the page.

1. Choose your unit system

- Select Metric if you work in meters and millimetres.

- Select US / Imperial if you work in feet and inches.

- Check the small unit labels under each input to confirm you are in the right mode.

2. Enter slab dimensions

- Measure the full length and width of your slab.

- Type these values into the slab length and width fields.

- For irregular shapes, use the largest rectangle that covers the main slab area.

3. Set spacing and cover

- Enter your target spacing along the length and spacing along the width (for example 200 mm or 8").

- Enter the concrete cover that your code or engineer requires (for example 50 mm or 2").

- Remember that this online rebar spacing calculator rounds the bar count up so the final spacing is equal to or less than your entered value.

4. Pick bar size and stock length

- Select the rebar size from the dropdown to match your design (for example Ø 10 mm or #4).

- Enter the stock bar length your supplier provides (for example 6 m or 20 ft).

- If you are not sure, use the default values and update them later when you have a price list.

5. Run the calculation and review the layout

- Click the “Calculate rebar” button.

- Check the summary box for: total bars in each direction, total length, estimated weight, and stock bar count.

- Look at the rebar layout preview to confirm the grid and cover visually make sense for your slab.

6. Adjust and refine your design

One of the main strengths of this concrete slab rebar calculator is how quickly you can test different layouts:

- Try a smaller spacing to see how much extra steel it adds.

- Switch to the next bar size up or down to compare total weight.

- Change the stock bar length if you find a better option from your supplier.

After a few iterations you will have a rebar layout that: matches your slab dimensions, stays within your target spacing, respects cover requirements and gives you a clear quantity for ordering. This makes the rest of your project planning much easier and helps you communicate clearly with engineers, suppliers and installers.

🔹 Online Rebar Calculator vs Manual Methods

Many builders and DIY users still size rebar using paper notes, rule-of-thumb spacing and printed rebar tables. While those methods can work, an online rebar calculator for slabs is faster, more consistent and less error-prone, especially when you update dimensions or switch between metric and US units.

Manual estimation challenges

- Re-entering the same formulas every time you change slab length or width.

- Confusing millimetres, centimetres, inches and feet when converting by hand.

- Miscounting bars when spacing, cover and inner dimensions all change at once.

- Forgetting to adjust total length or weight when you change bar size or spacing.

These small mistakes can easily lead to under-ordering rebar (which delays a pour) or over-ordering (which wastes money and storage space).

Advantages of this online rebar calculator

| Feature | Online rebar calculator | Manual / spreadsheet method |

|---|---|---|

| Unit handling | Automatic conversion between meters/feet and mm/inches | Manual conversions, higher risk of mix-ups |

| Bar spacing logic | Uses “equal or under” spacing with instant recalculation | Must recalc bar counts each time you tweak spacing |

| Visualisation | Live top-view grid showing cover and bar layout | No built-in visual check; needs sketching by hand |

| Total length & weight | Automatically updates both when bar size changes | Easy to forget to update weight after layout changes |

| Speed for “what-if” checks | Very fast; change a value and click once | Slower; re-enter multiple formulas or cells |

When manual checks still matter

Even with a powerful online tool, it is good practice to do a quick rough check by hand:

- Estimate a ballpark bar count by dividing inner dimensions by spacing.

- Check the order of magnitude of total length (for example “hundreds of meters” or “hundreds of feet”).

- Confirm that the steel weight looks realistic for your slab size and thickness.

When the manual sense-check and the calculator output are in the same ballpark, you can be far more confident in your rebar quantity before you order materials or schedule a concrete delivery.

🔹 Rebar Calculator Key Takeaways

This Rebar Calculator is built to give you a clear, visual and numeric estimate of the reinforcing steel needed for a rectangular concrete slab. Before you move on to ordering materials, it is helpful to recap what the tool is doing for you.

What this calculator gives you in seconds

- A rebar grid that respects your slab dimensions, cover and spacing.

- The number of bars in each direction plus a live visual of the grid.

- Total rebar length, steel weight and approximate number of stock bars.

- Automatic unit conversion between metric and US / Imperial, so you do not have to calculate mm↔in or m↔ft by hand.

How to get reliable results every time

- Measure slab length and width carefully and enter them in the correct units.

- Use realistic spacing (often 150–300 mm or 6–12") and an appropriate bar size for your load.

- Enter a cover value that matches local code or engineer guidance.

- Double-check the grid preview: bars should sit well inside the edges with a clear cover band.

Combining this tool with other planning steps

On a real job, rebar is only one part of the picture. After you are happy with the reinforcement layout:

- Use your concrete design to check slab thickness and mix strength.

- Plan formwork, joints, and where any penetrations or openings will go.

- Prepare a simple materials list including rebar, concrete, chairs, spacers and accessories.

If you often switch between metric and imperial when reading drawings or talking to suppliers, it can also help to keep the Length Conversion Calculator open in another tab for quick unit checks.

Once you are comfortable with how this rebar calculator works, you can reuse it across multiple projects – patios, sheds, driveways and small slab-on-grade floors – to keep your steel estimates consistent, fast and easy to explain to everyone involved in the build.

🔹 Rebar Calculator FAQ

The calculator estimates the number of bars in each direction, the length of each bar, the total rebar length, the approximate steel weight, and the number of stock bars you should order for a rectangular slab. It also shows a simplified top-view grid so you can visualise spacing and cover.

No. This tool is an estimator for simple slab layouts and material planning. Structural foundations, columns, beams and heavily loaded slabs must always be designed or checked by a qualified engineer using the relevant building codes for your region.

The weight is calculated from standard rebar tables using typical weights per meter (metric) or per foot (US). Real bars from a specific mill can vary slightly, so treat the result as a very good estimate, then let your supplier confirm the exact tonnage on the quote or delivery note.

The calculator uses an “equal or under” spacing rule. It rounds the bar count up so the maximum spacing between bars is no larger than your target spacing. That is why the final spacing in the results (and in the diagram) is often slightly tighter than the value you typed, which is usually better for crack control and safety.

No. The tool assumes straight bars running across the inner slab dimensions. It does not automatically add extra length for laps, hooks, starter bars or bent bars. If your design includes these details, you should either add an allowance to the total length or ask your engineer or supplier for a detailed bending schedule.

The calculator is optimised for a single rebar layer in a flat slab. Beams, grade beams, strip footings, retaining walls and slabs with two or more layers of steel require a different approach and often a bar schedule. For those elements, use this tool only for rough quantity ideas and rely on engineering drawings for final numbers.

Cover and spacing requirements depend on local building codes, exposure conditions and load levels. For small residential slabs, typical values might be 40–50 mm (around 1.5–2") cover and 150–300 mm (6–12") spacing, but you should always check the relevant standard or an engineer’s specification before you finalise your design.

Yes. Many slabs use both welded mesh and loose rebar. You can use the mesh for general crack control and this calculator for extra bars in high-stress zones (edges, around openings, under point loads). Just remember to add those extra bars manually to your overall materials list.

🔹 References & Sources

The rebar sizes, weights, spacing concepts and cover guidance used in this calculator and article are based on commonly accepted reinforced concrete practice and the reference materials below. Always check the latest version of your local standards and codes when designing structural elements.

| Type | Source / Author | How it was used |

|---|---|---|

| Website |

Blocklayer – Rebar Spacing Layout and Weight https://www.blocklayer.com/concrete/rebar-slabeng |

Used as a benchmark for typical slab rebar calculators, including the idea of bar spacing, total length estimation and visual slab layout for reinforcement. |

| Website |

Blocklayer – Concrete Calculator with Rebar (Metric & Inch) https://www.blocklayer.com/concrete/volume https://www.blocklayer.com/concrete/volumeeng |

Cross-checked general approach to combining concrete volume estimation with reinforcement quantity for multi-sided slabs and beam thickenings. |

| Website |

Wikipedia – Rebar & Reinforced Concrete https://en.wikipedia.org/wiki/Rebar https://en.wikipedia.org/wiki/Reinforced_concrete |

Background definitions and terminology for rebar, reinforcement grades and typical structural applications in reinforced concrete slabs. |

| Website |

Steelworld – Rebar Size Chart (Metric) https://steelworld.uk/pages/size-chart-reference |

Used to confirm approximate metric bar diameters and weight-per-meter values for 8–20 mm reinforcing bars (for the metric dropdown options). |

| Website |

Aesteiron – Rebar Weight Chart (Imperial) https://www.aesteiron.com/rebar-weight-chart.html |

Reference for typical weight-per-meter of common imperial bar sizes, helping to align the US bar weight figures used in the calculator. |

| Standard |

EN 1992-1-1: Eurocode 2 – Design of Concrete Structures (Example PDF extract) https://www.phd.eng.br/.../en.1992.1.1.2004.pdf |

Basis for general concepts of concrete cover, durability and reinforcement placement in European practice (used for explanatory text, not for full design). |

| Website |

Eurocode Applied – Concrete Cover Calculation https://eurocodeapplied.com/design/en1992/concrete-cover/… |

Additional reference for typical minimum concrete cover values for durability in different exposure classes, used to support the cover discussion. |

| Supplier data |

Harris Supply Solutions – Steel Rebar Sizes & Stock https://www.harrissupplysolutions.com/steel-rebar-sizes-stock.html |

Example of typical US stock bar lengths and sizes (20–60 ft) used to illustrate how to choose and price stock bar lengths in the calculator. |

| General practice | Contractor / engineering guides and typical residential slab details | Used for non-code-specific rules of thumb on slab rebar spacing ranges (approximately 150–300 mm / 6–12", light vs medium duty slabs) and for discussion of common real-life scenarios like patios, sheds and driveways. |

These references are provided for background information only. The Rebar Calculator on this page is an estimation tool and does not replace a full structural design or official code checks for reinforced concrete.